|

|

|

|

|

%20-%20Leica%20Geosystems%20-%20Leica%20Geosystems.files/pix.gif) |

| |

|

|

|

| Product Name: |

A30 Intrinsically safe and explosion-proof automatic coal pan meter |

| Model: |

A30 |

| Brand: |

|

| Price: |

|

|

|

|

| |

| Products |

1)It can be hung upside down on the inner top of the silo to measure the volume of the material in the silo, and it can scan 20,000 points per second.

2) High volume accuracy, volume error control within five thousandths.

(3) remote control of the scanner through the cable to scan, and real-time access to the silo graphic data, available laptop or desktop computer to control the rotation of the instrument and record the scan data.

4) Chinese software interface, simple operation, only one key is needed to scan the pile on site.

5)It can automatically reduce noise and filter, and can automatically generate the disk coal report in the format required by the user.

6) Lightweight instrument, waterproof, dustproof and anti-vibration, strong penetration ability of laser to dust.

7) rich data format, the point cloud can be exported to any format format required by the user.

8) can be integrated in SW31 portable coal pan meter to realize portable and fully automatic coal pan.

9) It can be upgraded to a handheld coal pan meter, which can be charted by walking around the pile.

10) It can be hung on the rail for bin scanning. |

| Technical parameters |

Scanning parameters

|

Horizontal scanning range

|

0-360° |

Vertical scanning range

|

0-360° |

Scanning accuracy

|

2cm |

Vertical angle accuracy

|

0.08° |

Horizontal angle accuracy

|

0.0005 |

Point picking speed

|

20,000 points/second

|

| Non-cooperative target measurement range |

Volume error

|

<0.5% |

Measurement range

|

30m |

| Laser Type |

Ranging laser wavelength |

905 |

Distance measuring laser type |

Class 1 human eye safety laser |

| Data Storage |

| Data Format |

ASC |

| Communication connector |

| Communication connector |

Self-locking cylindrical connectors |

| Physical indicators |

| Weight of the whole machine |

3.5kg |

| Volume |

145×145×308mm |

| Waterproof grade |

IP67 |

|

|

|

| Measurement method |

This scanner adopts high-frequency and high-precision scanning sensor in the industry, which can carry out horizontal 360-degree full field of view high-precision scanning, scanning 20,000 points per second (higher than the scanning frequency of similar products in Germany sick

5400 points), horizontal angle accuracy up to 2″, measuring range as far as 30 meters, point accuracy less than 3 cm; this product is light weight, the weight of the whole machine with the head is less than 4 kg, scanning once only takes 2-4 minutes. |

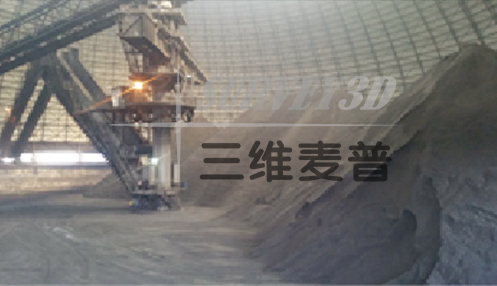

This product is suitable for hanging on the top of coal shed or silo, the user can use the computer software to control the scanner remotely through the data cable, and get the 3D coordinates of the surface of the whole pile with one key control; this product is suitable for single or multiple shed installation combination hanging measurement.

This product is suitable for single or multiple shed top installation combination suspension measurement. |

|

|

| The color rendering is as follows:

|

|

|

|

|

|

|

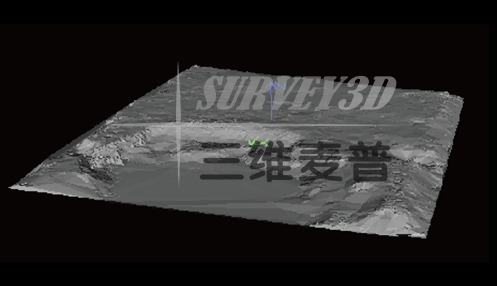

| The black and white rendering is as follows:

|

|

| |

|

| |

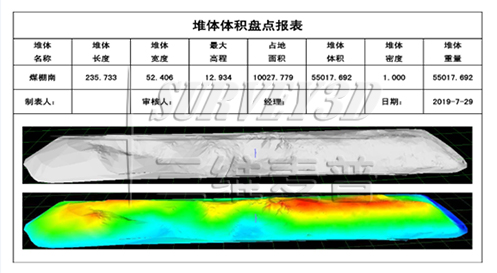

| The one-click report is as follows: |

|

| Applications |

In the field of power plants, steel mills and coal mines, there are often demands for discs in sheds, which are difficult to measure because of their large size and irregular shape.

This 3D laser scanner is a good solution to this problem. The scanner has a measuring range of up to 30 meters. It has a horizontal 360 degree rotating motor drive, and thanks to the friction brake technology and high precision angle encoder, the device can both manually and automatically rotate and scan. The scanning speed is fast, taking only a few minutes to scan through. Due to the good real-time of this coal pan system, it can greatly improve the automation management of power plant, save manpower and create benefits.

This product can not only realize the scanning of coal field by single instrument, but even network multiple laser scanners through LAN or wireless network, and set the frequency of scanning automatically through the control center software without human intervention. After scanning, the computer synthesizes and processes the data obtained by the 3D laser scanner, establishes a digital model of the coal field surface using digital fitting technology, calculates the volume of the coal pile according to the volume integration principle, and draws a three-dimensional graph of the coal field according to the digital model. The calculated volume number is then multiplied by the specific gravity of the coal to be the coal storage volume of the coal field. |

|

| Mining explosion-proof intrinsically safe 3D laser scanning |

|

| Volume measurement and variation analysis for power plants and other piles |

|

| 3D scanning of buildings and earthwork measurement |

|

| Digitalization and 3D modeling of coal field plants |

| |

| |

| |

|

|