|

|

|

| |

|

| Product introduction |

1) It can be hung upside down in the silo to measure the volume of materials in the silo and scan 20000 to 80000 points per second;

2) High precision, the volume error is controlled within 0.5%;

3) The scanner is remotely controlled by cables to scan and obtain the graphic data in the warehouse in real time;

4) Simple operation, Chinese software interface, only one key is needed to scan the material pile on site;

5) It can automatically reduce noise and filter, and automatically generate the coal inventory report in the format required by users;

6) A laptop or desktop computer can be used to control the rotation of the instrument and record the scanning data;

7) The data format is rich, and the point cloud can be exported to any format required by users (ASC);

8) It can be integrated on the SW31 portable coal counting instrument to realize portable full automatic coal counting;

9) It can be upgraded to a hand-held coal pan, which can be mapped by walking around the material pile once;

10) It can be hung on the guide rail for silo scanning. |

| Measurement method |

The depth measurement method is to obtain the vacancy depth in the silo by manually dropping the plumb bob to the surface of the material pile in the silo, and then calculate the volume of the material pile in the silo. Due to the uneven upper surface of the material pile in the silo, the measurement data has low accuracy, large error and other problems, and the measurement results are only for reference, and cannot be used as internal statistical data.

3D laser scanning technology is a new means of data acquisition, which has the characteristics of initiative, high precision, rapidity, etc. It uses the principle of laser ranging to quickly reconstruct the line, surface, volume and other omnidirectional 3D models of the measured object by recording the 3D coordinates and texture information of a large number of dense point clouds on the surface of the measured object. Its application in silo capacity measurement can improve the traditional problems of long measurement time, high work intensity and low accuracy. |

|

|

| Project Case |

As a storage and measuring instrument, the accuracy of silo capacity measurement directly affects the economic interests of enterprises. In this project, three-dimensional Mipo Company uses A100 three-dimensional laser scanner to collect data from the silo.

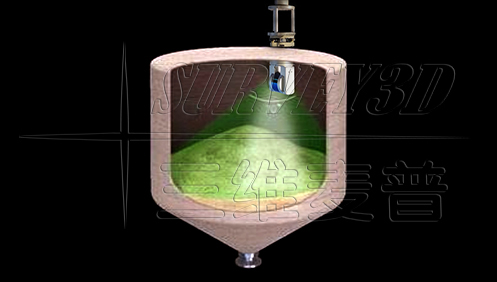

When measuring the silo capacity, invert the 3D scanner through a special installation device and fix it at the silo metering port to ensure that the 3D laser scanning equipment extends into the proper position of the silo port, and level the installation device. Set the parameters of the control system such as speed and rotation angle outside the silo. The rotation speed and angle will be horizontally rotated by 0 ° - 180 ° according to the set parameters, so as to scan the surface of the material pile in the silo into a three-dimensional point cloud surface. The three-dimensional laser scanning technology can not only realize the rapid and accurate measurement of the silo, but also use the obtained spatial point cloud data to quickly establish the surface model of the tanker, providing reference data for the detection of the ash level of the silo internal surface area and other applications |

|

|

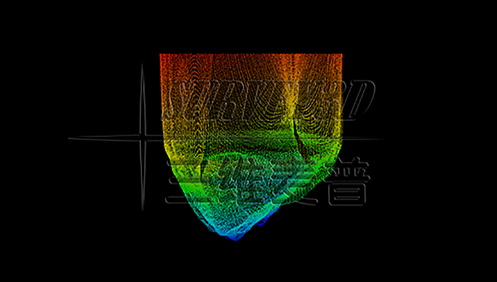

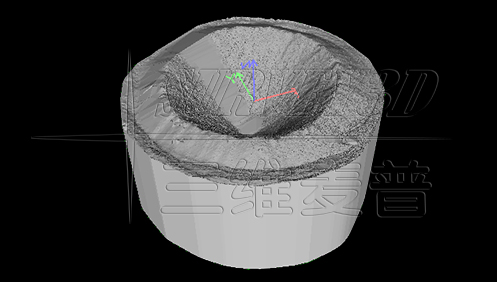

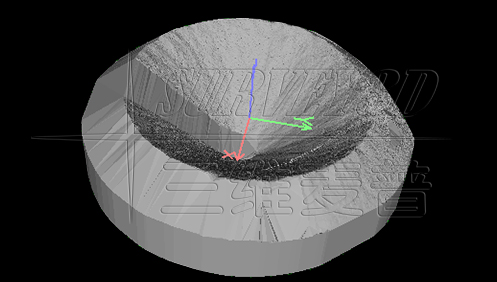

| The point cloud diagram is as follows:

|

|

|

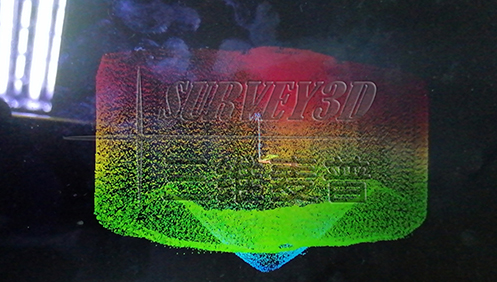

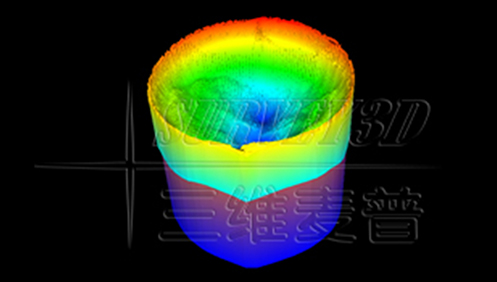

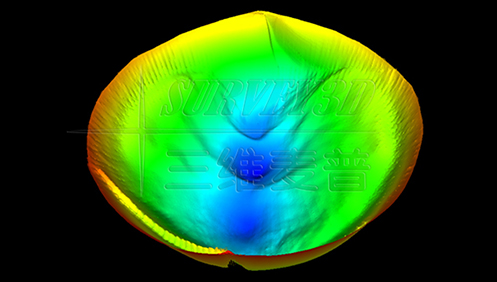

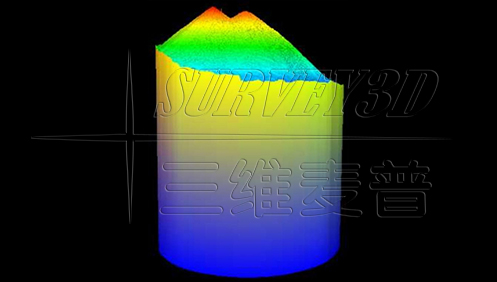

| The color rendering is as follows:

|

|

|

|

|

|

| The black and white rendering is as follows:

|

|

|

| Technical parameter |

Angle measurement |

Horizontal scanning range |

0-360° |

| Vertical scanning range |

-70°到+90° |

Scanning accuracy |

2cm |

| Vertical angle accuracy |

0.08° |

Horizontal angle accuracy |

0.0005 |

| Sampling speed |

2-8万点/秒 |

Non cooperative target range |

Volumetric error |

<0.5% |

Range |

160m |

| Laser type |

Ranging laser wavelength |

905 |

Ranging laser type |

Class 1 Eye Safe Laser |

Data storage/communication |

Data format |

ASC |

| Communication connector |

| Communication connector |

Self locking cylindrical connector |

Physical indicators |

| Operating Weight |

3.8kg |

| Volume |

110×120 x 252mm |

| Waterproof grade |

IP67 |

| |

|

|

| |

| Application area |

In the field of power plants, steel plants and coal mines, there is often a demand for coiled materials in silos or sheds. Due to the large volume and irregular shape, it is difficult to measure.

This 3D laser scanner is a good solution to this problem. The scanner has a range of up to 100 meters. It is driven by a horizontal 360 degree rotary motor. Due to the friction braking technology and high-precision angle encoder, the equipment can rotate and scan manually and automatically. The scanning speed is fast. It only takes a few minutes to scan once. Due to the good real-time performance of the coal handling system, the automation management level of the power plant can be greatly improved, saving manpower and creating benefits.

This product can not only realize the coal yard scanning of a single instrument, but also can connect multiple laser scanners via LAN or wireless network, and automatically set the scanning frequency through the control center software without manual intervention. After scanning, the computer synthesizes and processes the data obtained by the three-dimensional laser scanner, uses the digital fitting technology to establish the digital model of the coal yard surface, calculates the volume of the coal pile according to the volume fraction principle, and draws the three-dimensional graphics of the coal yard according to the digital model. The calculated volume number multiplied by the specific gravity of coal is the coal storage in the coal yard. |

| |

| |

| |

|

|