|

|

|

| |

%20-%20Leica%20Geosystems%20-%20Leica%20Geosystems.files/pix.gif) |

| |

|

|

|

| Product Name: |

Shed aerial rail trolley |

| Model: |

APM-2 |

| Brand: |

|

| Price: |

|

|

|

|

| Products |

1)Large span, long flight time, aerial inventory of coal piles inside the arch.

2) fixed route in one installation, stable and deviation-free, simple and easy to operate.

3)Say goodbye to tedious operation, one key forward and backward, full scale adjustable air speed, one key aerial photography.

4) no no-fly zone restrictions, more people can also work safely, refusing to black fly without a driver's license.

(5) split design, quick installation, easy to carry.

6) industrial-grade airframe, dustproof and waterproof windy weather, the same operation, the environmental requirements are very low.

7) high-definition combined with a three-axis gyroscope stabilization system, no camera shake, clearer photos.

8) automated data processing, software automatically generates three-dimensional models and volume statements.

9) generating models for true color three-dimensional model, material pile rich in detail.

10) can realize unified inventory partition calculation volume, able to get rid of invalid data outside each field area.

11) external camera, also can patrol the coal field situation.

12)Break through the traditional drone aerial photography no-fly and driving license restrictions, and break through the aerial photography can not be operated in the shed. |

| |

| Design Solutions |

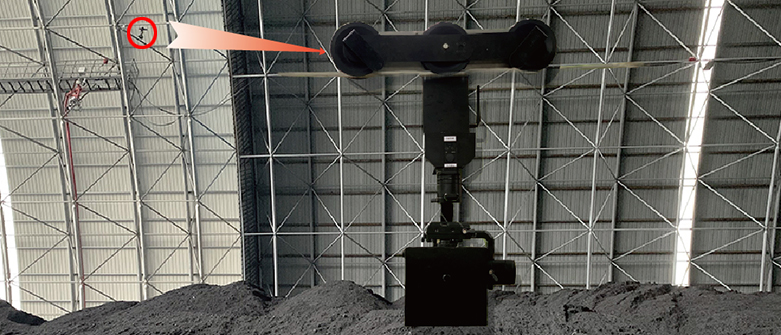

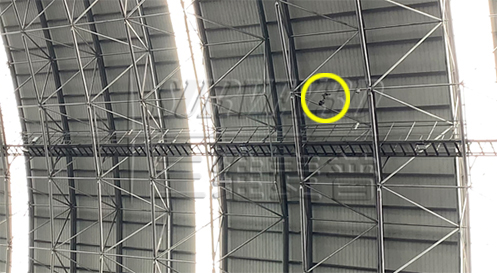

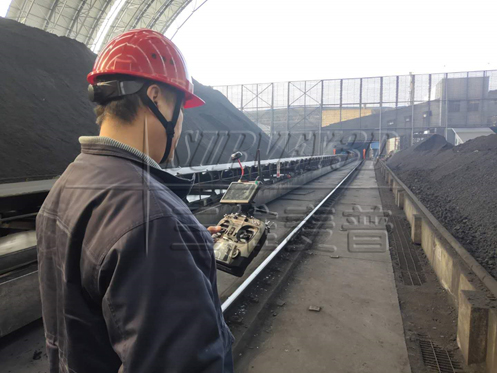

Set up tracks for the top of the coal yard, and each track is equipped with a track trolley, and each track trolley carries a fully automatic steady direction head solution.

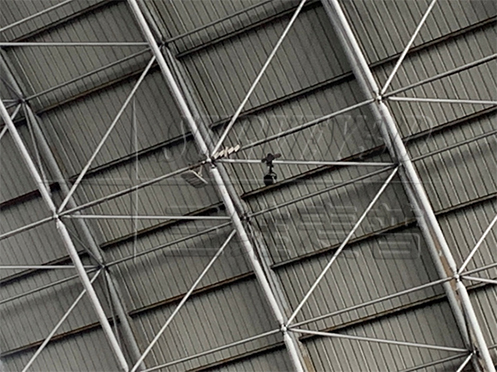

The details are as follows: according to the length of the coal yard, tracks are installed on the top of the coal yard. The tracks are equipped with track trolleys, and POS modules, steadicam heads and cameras are suspended under the track trolleys to collect data for the whole coal yard, which can realize the full range coverage of coal piles in this coal yard.

1. Preparation

Set up the track, track trolley, gimbal and camera on the top of the coal shed, and the preparation work is finished.

2. Aerial photography work

After the track trolley enters the starting point of aerial photography, start the switch, the track trolley moves forward at a uniform speed and automatically completes the aerial photography work, after the work is finished, start the remote control again and let the trolley return to the starting point. |

|

|

|

3. Acquisition of data

After shooting, data processing is performed and the rail carriage is retrieved for the next use.

|

|

4. System contains

The system includes: 1 set of track and track trolley, 1 set of automatic steady directional head, 1 set of aerial camera, 1 set of aerial remote control, 1 set of map display equipment and other equipment. |

|

|

|

|

|

| Measurement method |

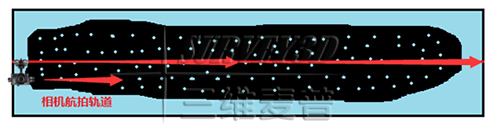

| The design solution is to set up a number of rail channels in the middle of the coal field, and to capture the data by photographing the coal field through the movement of the camera carried by the gimbal on the rail trolley. During the aerial photography, the rail trolley is controlled by the remote control terminal to move at a uniform speed on the rail, and the pitch rotation of the gimbal it carries drives the high-precision camera to realize the aerial photography of the coal field. The process of aerial photography is as follows: the red line is the route of aerial photography, and the process of aerial photography of the coal field is completed from left to right. |

This design solution allows a single steadicam + aerial camera to work individually, while converting the aerial photography results into 3D graphic data of the current coal field after acquiring the data in situ.

|

1. Aerial photography method

After starting the trolley switch, the trolley runs at a uniform speed. The carriage has a high precision gimbal, which can realize the camera self-stabilization.

2. Data processing

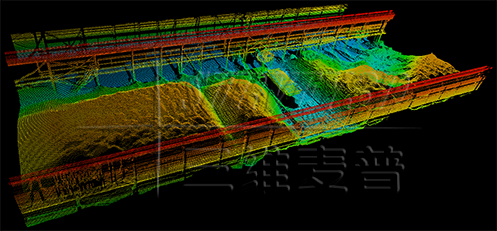

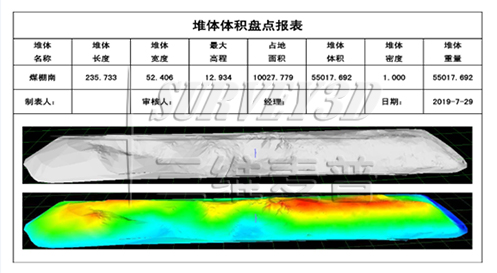

After the aerial photography is finished, control the track trolley to return to the position, and then download all the photos of the aerial photography from the camera through the acquisition, and carry out data processing after the download is finished to establish the three-dimensional graphics and reports of the coal field. The display content includes the length, width and height of the coal strip, floor space, pile volume, density and weight.

The effect of coal pan is as follows. |

|

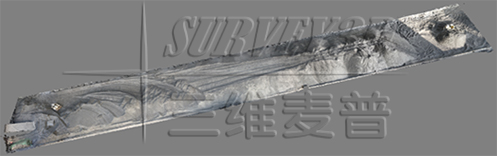

| The aerial view is as follows:

|

|

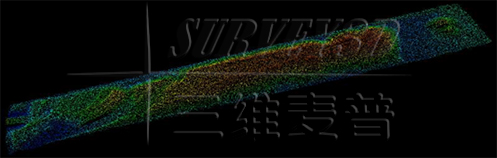

| The point cloud diagram is as follows:

|

|

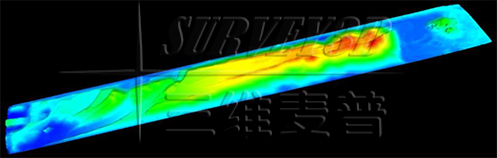

| The color rendering is as follows:

|

|

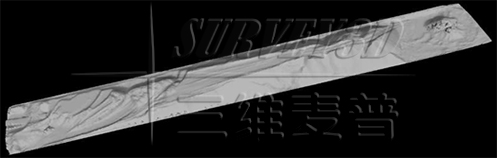

| The black and white rendering is as follows:

|

|

| Technical parameters |

Measurement accuracy |

Climbing |

30° |

Working hours |

60 minutes |

Speed |

133cm/s |

Remote Control Distance |

900M(related to environmental disturbances) |

Camera Pixels |

2010million |

Picture transfer display |

5inch |

Motor voltage |

24V |

Battery Capacity |

21000mA |

Overall weight |

5.4kg |

Main body material |

Aluminum |

Track Type |

Light Rail |

Processing Software |

Processing Software |

Software running platform Windows 7 and above |

Fully automated high-precision 3D modeling, disc coal accuracy of 99.5% or more |

Ability to get rid of invalid data outside the coal field area, ability to calculate volume and weight |

Can realize the function of unified inventory, partition calculation volume, data editing function |

Display all coal field model drawings under one interface and support 3D dynamic browsing |

Color display of model color, different coal fields can be displayed in different colors, easy to distinguish |

Inclined ground measurement, coal pile 3D model map can be color elevation rendering, easy datum selection |

Invisible foundation surface processing function: For the situation that the foundation surface is deeply buried under the coal pile, this function can be used to automatically process and eliminate the error. |

Software can be integrated with other laser counting devices for future upgrades and expansions to automatically generate standard format reports |

|

| |

| Equipment Benefits |

The protection level of the device is IP67. Since dust can affect the clarity of the photos, the measurement should be made when the dust density is low. The working temperature range of this equipment is -20℃-50℃.

There are cases in coal yard where there are multiple coal types per coal shed and multiple piles of the same coal type, using this equipment can distinguish the inventory, and the shape of coal piles is not restricted. The scanned data in the data processing software can truly show the actual situation of the site, the actual coal pile shape, and it is easy for people to identify each pile.

The data processing software is developed by our company independently. And it has obtained "Computer Software Copyright Registration Certificate" and "Software Product Certificate". The software running environment supports win7, win8, winxp and win10, and the software can be upgraded and maintained for free. |

| |

| |

| |

|

|