|

|

|

|

|

%20-%20Leica%20Geosystems%20-%20Leica%20Geosystems.files/pix.gif) |

| |

|

|

|

|

| Product Name: |

Conveyor on coil coal system |

| Brand: |

Beijing Survey3d System |

| |

|

| |

|

|

|

|

| Products |

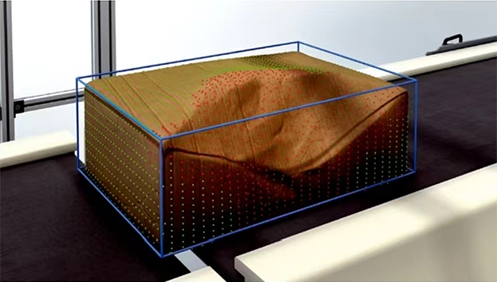

Conveyor scanning system is mainly used for conveyor flow measurement, compared with the traditional belt scale weighing measurement method is more accurate, stable, and three-dimensional visualization, can improve the efficiency of material storage management, realize the fine management of material into the consumption, for the factory production of open source and cut costs.

The whole system uses remote control of instrument operation and data transmission, and can be used in harsh environments that are not suitable for long-term human stay. The equipment is well sealed, waterproof and dustproof. The scanner of this system adopts high-frequency and high-precision scanning sensor in the industry, which can carry out horizontal 360° full-field high-precision scanning. Scanning 20,000 points per second, horizontal angle accuracy of up to 2″, measuring range as far as 60m, point accuracy of less than 2cm; this product is light weight, the weight of the whole machine is less than 4kg.

|

| Work Program |

According to the site situation, the laser scanner is installed upside down above the conveyor belt, combining the scanner scanning section with the conveyor belt movement travel information to scan the material on the conveyor belt in fine detail, the scanning resolution can reach millimeter level, to ensure the integrity and accuracy of the point cloud coverage. The client software can scan the material on the conveyor belt in real time by simply clicking "Start Scanning", and obtain the 3D coordinate data of the measured pile for automatic 3D modeling, display and calculation, thus completing the automation from original data collection to report generation, realizing accurate measurement and efficient management of the pile.

|

| Product Description |

The scanner adopts high-frequency and high-precision scanning sensor in the industry, which can carry out horizontal 360-degree full-field high-precision scanning, scanning 20,000 points per second, horizontal angle accuracy as high as 0.0005°, measuring range as far as 60 meters, point accuracy less than 2 cm; light weight, the weight of the whole machine with the head is less than 4 kg, and it only takes 2-4 minutes to scan once; suitable for suspension installation on top of coal shed or silo, the user uses the computer The user can control the scanner remotely through the data cable, and get the 3D coordinates of the whole surface of the pile with one key control; suitable for single or multiple shed top installation combination suspension measurement.

|

| Product parameters |

Scanning parameters |

Horizontal scanning range |

0-360° |

Vertical scanning range |

0-360° |

Scanning accuracy |

2cm |

Vertical angle accuracy |

0.09° |

Horizontal angle accuracy |

0.0005 |

Point picking speed |

20,000 points/second |

| Non-cooperative target measurement range |

Volume error |

<0.5% |

Measurement range |

60m |

| Laser Type |

Ranging laser wavelength |

905 |

Distance measuring laser type |

Class 1 human eye safety laser |

| Data Storage |

| Data Format |

ASC |

| Communication connector |

| Communication connector |

Self-locking cylindrical connectors |

| Physical indicators |

| Weight of the whole machine |

3.5kg |

| Volume |

145×145×308mm |

| Waterproof grade |

IP67 |

| Operating temperature |

-40℃-+60℃ |

| Storage temperature |

-40℃-+80℃ |

|

|

|

| |

| Applications |

1、Digitalization of coal yards in thermal power plants, volume measurement of coal-fired conveyor belts;

|

.jpg)

2、Online volume monitoring of steel, metallurgy, chemical and cement material conveyors;

|

| |

.jpg)

3、Port and terminal conveyor belt material volume measurement;

|

4、Mine, earthwork excavation and mining conveyor belt site measurement。 |

|

|